Add your promotional text...

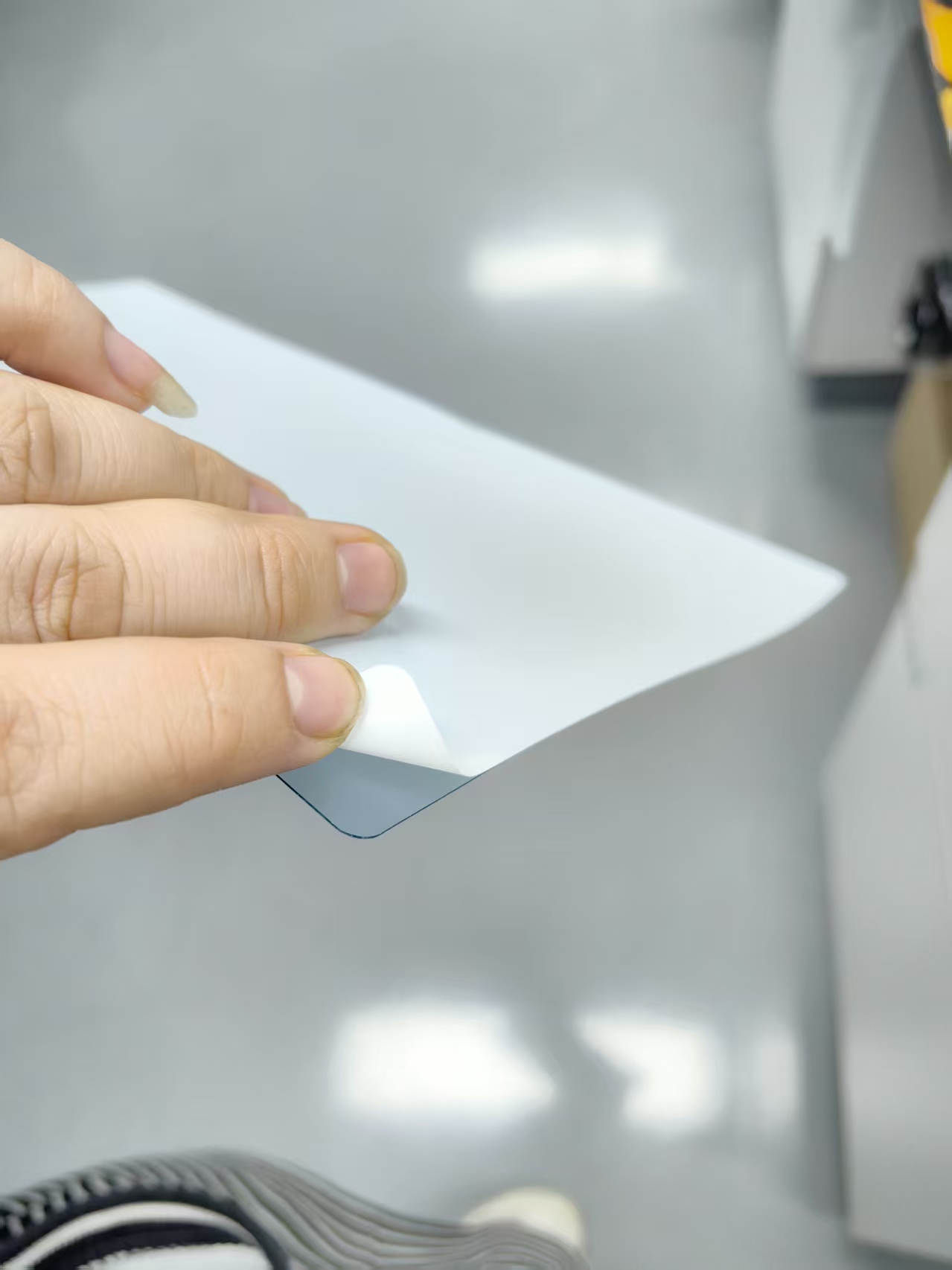

Premium Sunroof Protection Film – Ultimate Comfort for Your Drive

X-270C 1 2MIL/X170C 8MIL

¥3300.00¥3000.00

When the sun is shining bright, don’t let it ruin your journey. Our high-performance sunroof film is engineered to deliver unbeatable protection and comfort, combining cutting-edge technology with durable materials that stand the test of time.

Why Choose Our Sunroof Film?

✅ 99% UV RejectionShield yourself and your car’s interior from harmful UVA/UVB rays. Prevent fading of seats, dashboards, and upholstery—keep your car looking brand new for longer.

✅ Superior Heat InsulationReduce cabin temperature by up to 60% on hot days. Say goodbye to burning seats and steering wheels. Enjoy a cool, comfortable ride without cranking up the AC—save fuel and cut energy costs.

✅ Crystal Clear VisibilityNo foggy haze, no signal interference. Our film maintains 100% optical clarity, preserving your sunroof’s panoramic view while blocking glare. Drive safely with unobstructed sightlines.

✅ Scratch & Weather ResistanceCoated with a hard-wearing scratch-resistant layer, our film withstands debris, rain, and extreme temperatures. Resistant to yellowing and peeling—long-lasting protection for 8+ years.

✅ Universal Fit & Easy InstallationCustom-cut to fit any sunroof size and shape. Compatible with panoramic, sliding, and fixed sunroofs. Easy to install with bubble-free adhesive—ideal for professional installers or DIY enthusiasts.

OEM & Wholesale Services

As a leading manufacturer, we offer flexible OEM/ODM customization:

• Custom logos, packaging, and film thickness

• Bulk stock available for fast global shipping

• Competitive factory-direct pricing for distributors, retailers, and auto shops

• Technical support and after-sales service

Order Now & Upgrade Your Car’s Comfort Today!Global Shipping | Fast Delivery | Quality Guaranteed

ENXUN X-270C Product Specification Sheet | |||

Item | Testing Method | Value | Unit |

Total Product Thickness | GB/T 6672 | 12±0.3 | mil |

Elongation at Break | ASTM D-882 | ≥300 | % |

Tensile Strength | QC/T 1171-2022 | 20±5 | MPa |

Tear Resistance | QC/T 1171-2022 | ≥50 | KN/m |

UV Blocking Rate | GB/T 2680 | ≥90 | % |

Puncture Resistance | QC/T 1171-2022 | ≥130 | N |

Aging Resistance | QUV (0.5W, 40℃, 340nm, 120min cycle, 18min spray), 3200 hours | No cracking, no blistering, no degumming | |

Heat Repair Performance | Scratched 10 times with a fine copper brush under load of 110g/cm²; repaired with ~70℃ hot water or hot air | No scratches on surface | |

High/Low Temperature Resistance | Alternated between 80℃ (high temp) and -40℃ (low temp) for 4 hours each cycle, total 168 hours | No cracking,no blistering, no delamination | |

Acid & Alkali Resistance | Immersed in HCl (pH 5-7) and NaOH (pH 7-10) for 30 minutes each | No abnormalities | |

Abrasion Resistance | QC/T 1172-2022 | Haze change before/after friction ≤1.5% | |

Stone Chip Resistance | SAE-J400 | Grade 10 | |

Product Parameter | Details | ||

Product Substrate | Lubrizol | ||

Product Adhesives | Ashland | ||

Product Coating | KCC | ||

Product Thickness | 12±0.3mil | ||

Base Material Origin | USA | ||

Coating Origin | Japan | ||

Adhesive Origin | USA | ||

Repair Functionality | Heat Repair | ||

Residue-Free Removal | No | ||

Warranty Years | 5yrs |